The Renishaw REVO® 5-axis system brings together the power of multiple advanced measurement technologies into one flexible, high-performance platform. This breakthrough helps manufacturers improve inspection speed, accuracy, and automation—meeting the demands of modern production.

5-Axis Innovation – Faster, Smarter, More Efficient Measurement

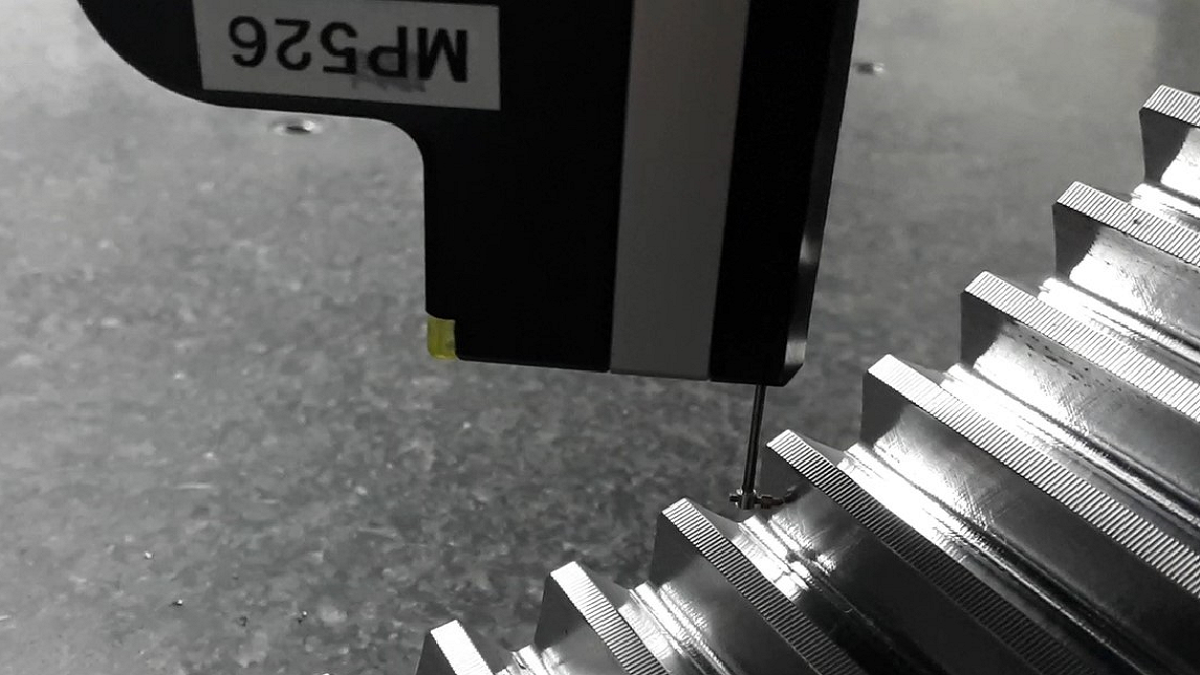

Unlike traditional 3-axis CMM systems, REVO integrates two rotary axes directly into the probe head, enabling smooth and dynamic 5-axis motion. This allows the probe to follow complex geometries with ease—without moving the entire machine structure.

Key advantages include:

- Significantly faster inspection times

- Improved measurement accuracy

- Reduced mechanical wear, extending CMM lifetime

- Higher part throughput within the same shift

REVO helps manufacturers boost productivity while maintaining strict quality standards.

One System – Unlimited Measurement Capability

REVO is not limited to a single measurement method. The system supports:

- Tactile probing

- Optical measurement

- Surface finish inspection

Thanks to its multi-sensor capability, REVO is ideal for a wide range of industries, including:

- Aerospace components, turbines, and blades

- Precision mechanical parts

- Automotive components and molds

- Complex shapes requiring high-accuracy inspection

All executed on one flexible, uncompromising platform.

Fast Calibration – Maximize Machine Uptime

While traditional probe systems require hours for full calibration, REVO completes a full-angle calibration in just 15 minutes. This calibration data is automatically applied to all probe positions and measurement angles.

The result:

- Minimized downtime

- Shorter setup time

- Significantly increased inspection productivity

Programming Freedom – Optimized Inspection Workflow

REVO’s intelligent 5-axis architecture allows engineers to program complex parts easily, without restrictions on probe angles or access points.

The system also integrates seamlessly with leading metrology software, enabling:

- Automated and streamlined inspection routines

- Consistent, repeatable results across shifts

- Reduced dependence on operator skill

The Future of High-Precision Metrology

The REVO® system delivers the perfect combination of flexibility and accuracy, offering a superior 5-axis measurement solution for advanced manufacturing. With rapid calibration, multi-sensor capability, and unmatched programmability, REVO is a powerful tool for factories moving toward smart, automated production.

For detailed consultation on CMM solutions and advanced metrology technologies, please contact the expert team at Gera Hi-Tech Vietnam.