Ensuring Cleanliness and Product Quality

In industries such as aerospace, automotive, semiconductors, and medical devices, maintaining the highest level of cleanliness is critical. Even a microscopic particle can affect performance, reduce product lifespan, or — in the case of medical implants — pose serious health risks.

To meet strict cleanliness standards, manufacturers apply advanced cleaning processes, many of which now use water-based solutions to comply with environmental regulations. However, no matter how thorough the cleaning process is, verification is essential. This is where Liquid Particle Counters (LPCs) come into play.

Why LPCs Matter

LPCs are core instruments for real-time contamination monitoring in cleaning fluids. They deliver immediate feedback, helping manufacturers validate the cleaning efficiency of every process cycle.

Advanced models, such as the Lighthouse Vertex50, offer 50 nm sensitivity and support continuous, high-accuracy monitoring — enabling optimal contamination control throughout production.

Industrial Cleaning Methods and the Role of LPCs

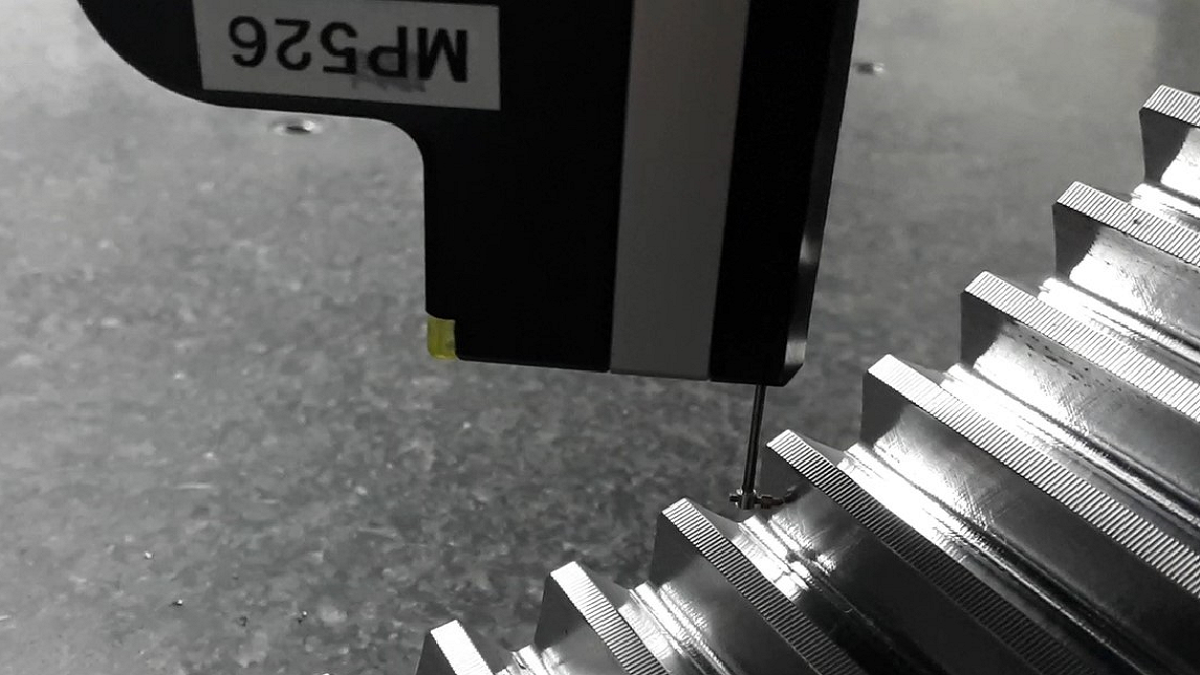

1. Ultrasonic Cleaning

High-frequency sound waves generate millions of microscopic bubbles that dislodge contaminants from complex surfaces.

Industries: Semiconductors, Aerospace, Medical Devices, Automotive, Data Storage

LPC Role: Measures particle concentration in the cleaning solution to verify final cleanliness.

2. Immersion Cleaning

Parts are immersed in a solvent or water-based solution, often combined with ultrasonic cleaning for improved efficiency.

Industries: Semiconductors, Aerospace, Medical Devices, Automotive

LPC Role: Compares particle levels before and after cleaning to assess process effectiveness.

3. CO₂ Cleaning

Uses solid or liquid carbon dioxide to remove contaminants without leaving residues.

Industries: Semiconductors, Medical Devices, Aerospace, Data Storage

LPC Role: Confirms there are no residual particles remaining after cleaning.

4. Passivation

Removes ferrous particles from stainless steel to enhance corrosion resistance according to ASTM A380 and A967.

Industries: Aerospace, Medical Devices

LPC Role: Verifies complete particle removal and ensures surfaces meet cleanliness standards.

Where LPCs Are Used Across Industries

LPCs ensure cleanliness for various precision components, such as:

Aerospace

- Optical sensors

- Turbine blades

- Fuel system components

Automotive

- Fuel injectors

- Brake systems

- Transmission parts

Medical Devices

- Heart valves

- Catheters

- Surgical implants

Semiconductors

- Silicon wafers

- Photomasks

- Chip packaging

Data Storage

- HDD components

- Magnetic heads

Key Benefits of Using LPC Technology

LPCs deliver value far beyond particle counting:

✔ Ensure Compliance With Industry Standards

Guarantee components meet strict international cleanliness requirements.

✔ Enhance Quality Control

Reduce contamination risks and prevent product failures.

✔ Optimize Manufacturing Processes

Real-time monitoring supports data-driven improvements.

✔ Protect Cleanroom Environments

Prevent cross-contamination during production.

✔ Strengthen Customer Confidence

Superior cleanliness translates into higher product reliability.

Conclusion

From ensuring the safety of medical implants to protecting semiconductor performance, Liquid Particle Counters (LPCs) play an essential role in precision parts cleaning.

By integrating LPC technology, manufacturers can:

- Ensure product reliability

- Comply with industry regulations

- Maintain exceptional quality standards