MAINTENANCE AND REPAIR SERVICES, CALIBRATION OF AIRBORNE PARTICLE COUNTERS

In various sectors such as pharmaceuticals, healthcare facilities, cleanrooms, and industrial environments, the quality of air plays a critical role in ensuring safety, product integrity, and regulatory compliance. Airborne particle counters are indispensable tools in monitoring and maintaining air quality by measuring the concentration and size distribution of airborne particles.

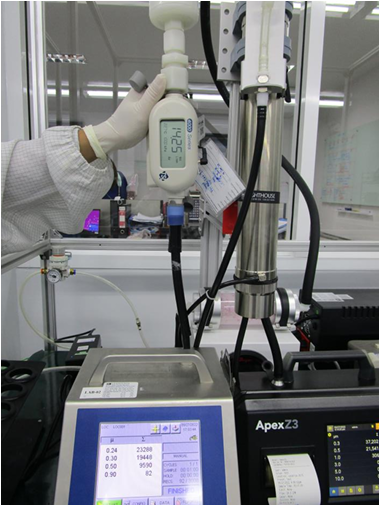

ApexZ3 airborne particle counter

However, to ensure reliable and accurate results, regular calibration of airborne particle counters is paramount. This article delves into the importance of calibrating airborne particle counter devices in maintaining air quality standards.

1. Accuracy Assurance

Airborne particle counters are relied upon to provide precise measurements of airborne particle concentrations. Calibration ensures that these instruments accurately detect and count particles of various sizes, thereby providing reliable data for assessing air quality. Without calibration, there is a risk of inaccurate measurements, leading to erroneous conclusions about the cleanliness of the air.

Accuracy checked and verified

2. Compliance with Standards and Regulations

Many industries are subject to stringent standards and regulations governing air quality. Calibration of airborne particle counters is essential to ensure compliance with these requirements. Regular calibration ensures that the instruments meet specified accuracy levels and adhere to regulatory guidelines, thus enabling organizations to demonstrate conformity with industry standards and regulatory mandates.

3. Maintenance of Cleanroom Environments:

In environments such as cleanrooms, where even minor particle contamination can compromise product quality or research outcomes, calibrated airborne particle counters are indispensable. These instruments help monitor and maintain the cleanliness of the air by detecting and quantifying particles present. Regular calibration ensures that the particle counters accurately assess air quality, enabling proactive measures to maintain cleanroom standards.

4. Quality Control in Pharmaceutical and Healthcare Settings

In pharmaceutical manufacturing facilities and healthcare settings, airborne particle counters play a crucial role in ensuring the sterility and safety of products and environments. Calibration of these instruments is vital to guarantee accurate monitoring of airborne particulate levels during critical processes such as sterile compounding or operating room procedures. Calibrated particle counters contribute to maintaining the integrity of pharmaceutical products and safeguarding patient health.

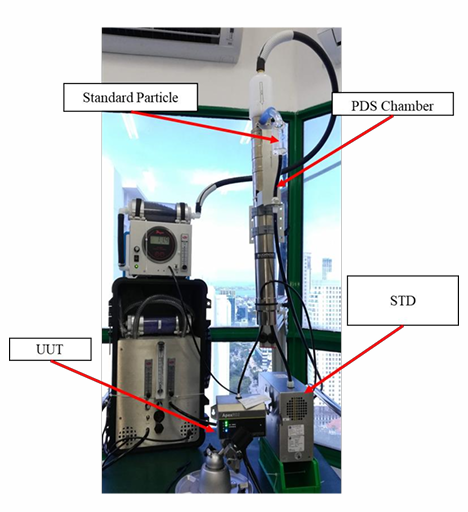

PDS (Particle Delivery System) system for calibration

5. Confidence in Research and Development:

In research and development laboratories, precise measurements of airborne particles are essential for conducting experiments and analyzing data accurately. Calibrated airborne particle counters provide researchers with confidence in their findings, allowing them to draw valid conclusions and make informed decisions based on reliable data. Calibration ensures the integrity of research outcomes and contributes to the advancement of scientific knowledge.

In conclusion, the calibration of airborne particle counters is indispensable for maintaining air quality standards, ensuring compliance with regulations, and safeguarding product integrity and human health in various industries and environments.

By investing in regular calibration procedures, organizations can uphold the reliability and accuracy of their air quality monitoring systems, thereby enhancing overall operational efficiency and safety.

With a team of officially trained engineers and fully invested infrastructure, Gera Vietnam commits to providing the best-quality calibration, maintenance, and repair services, ensuring that our customers’ particle counting machines always operate efficiently and achieve accurate results.