WHAT IS CLEANROOM INSPECTION?

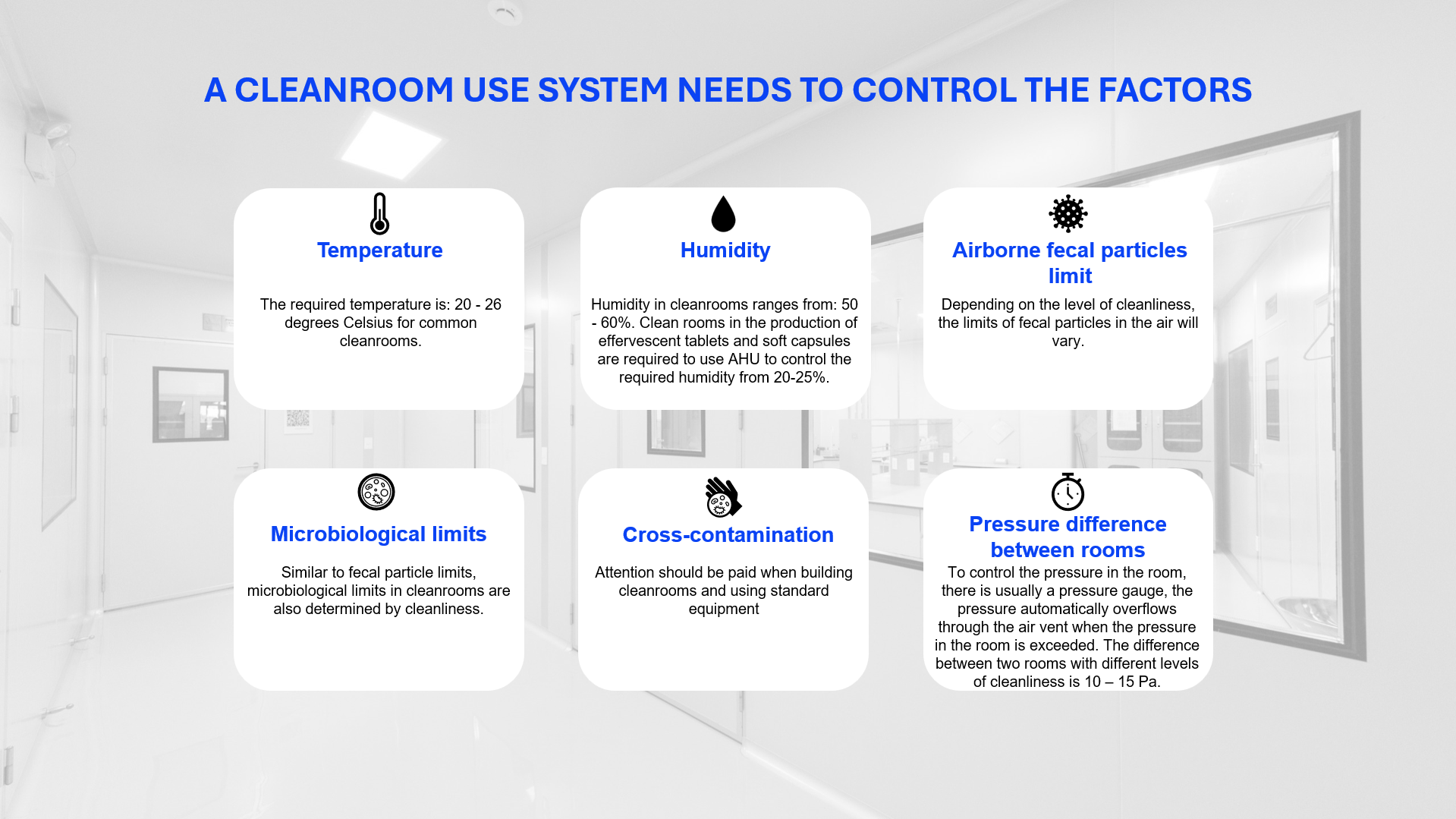

Cleanroom inspection is the process of verifying and certifying that the cleanroom environment meets the requirements and standards that have been set. This inspection process typically involves testing, measuring and testing parameters such as air flow, pressure, cleanliness, bacterial and virus concentrations, as well as performance testing of critical equipment and systems in cleanrooms.

WHY DO WE NEED TO MEASURE AND CALIBRATE CLEANROOMS REGULARLY?

A cleanroom is a place that is usually designed to avoid environmental impacts on production or scientific research.

– In industry, cleanrooms are used in the manufacture and maintenance of hardware such as integrated circuits (ICs) and hard disk drives.

– In biotechnology and medicine, clean rooms are used as needed to ensure the environment is free of bacteria, viruses or other pathogens.

– Since the conditions are so strict, assessing the cleanliness level of a cleanroom is essential and important.

THE IMPORTANCE OF CLEANROOMS

Cleanroom inspections not only ensure that the working environment meets the requirements of cleanliness and safety, but also help ensure product quality and save resources. The benefits of regular cleanroom inspections include:

– Product Quality Assurance: In many industries such as pharmaceuticals, medical products or electronics, product quality can be seriously affected by contamination. Cleanroom inspections help ensure that products are manufactured in a controlled environment, thereby minimizing the risk of contamination and product defects.

– Protect Employee Health: A clean working environment helps protect the health of employees, preventing the spread of bacteria and viruses. This is especially important in the medical and food industries.

– Regulatory Compliance: Many industries must comply with regulatory regulations and standards. Cleanroom inspections help ensure that these requirements are fully met

– Optimize Performance: Cleanroom equipment and systems need to operate stably and efficiently to ensure the highest quality working environment. Periodic inspections and maintenance help maintain optimal performance.

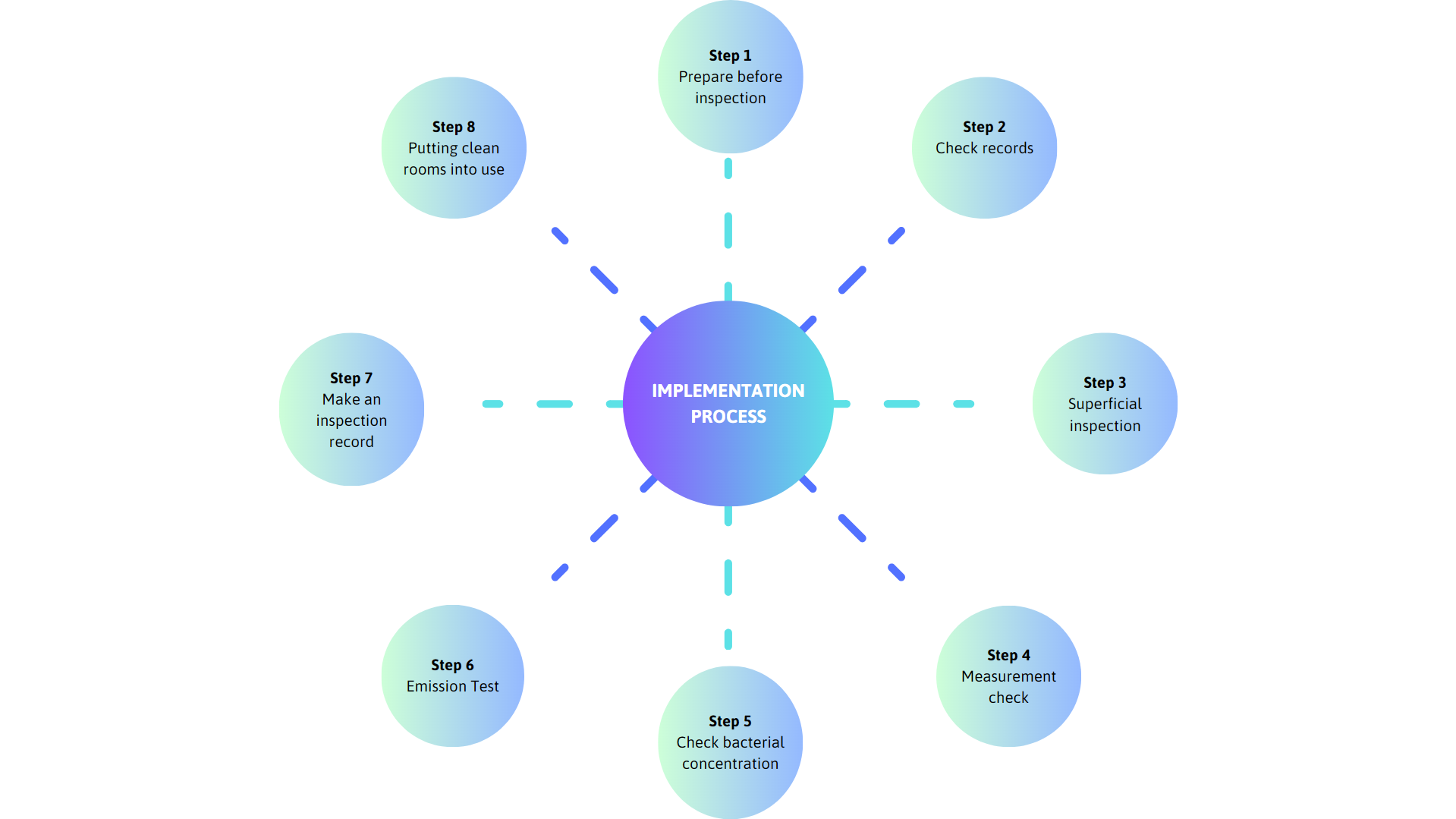

CLEANROOM INSPECTION IMPLEMENTATION PROCESS