Introduction

In cleanroom environments, contamination control goes beyond counting airborne particles — it also involves monitoring viable contamination, such as mold, bacteria, or fungal spores capable of growth.

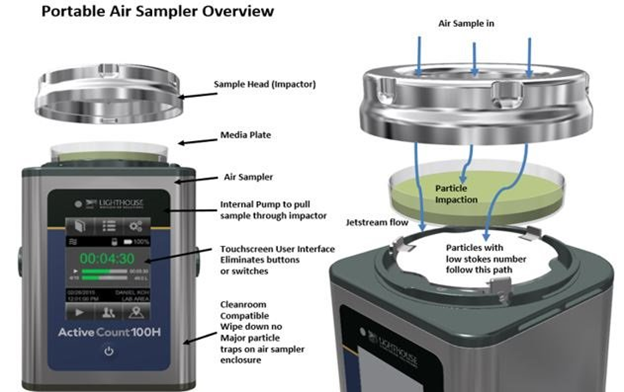

While a particle counter detects the presence of contaminants, only an active air sampler can identify what kind of viable microorganisms are present in the air.

As experts in cleanroom monitoring and environmental control, Gera Hi-tech Vietnam shares the 8 essential featuresyou should look for when choosing the right Active Air Sampler for your cleanroom.

1️⃣ Cleanroom-Compatible Design

Every instrument used inside a cleanroom must be made from materials that resist particle generation, are easy to wipe down and disinfect, and feature a smooth, gap-free surface to prevent microbial buildup.

A hygienic and sealed design helps maintain sterile integrity throughout the air sampling process.

2️⃣ Built-In Compliance with International Standards

Cleanrooms in industries like pharmaceuticals, semiconductors, and medical devices are governed by strict standards such as ISO, EU GMP, and FDA regulations.

Your active air sampler should be fully compliant with ISO 14698-1, providing audit-ready data trails and simplifying documentation during GMP or ISO audits.

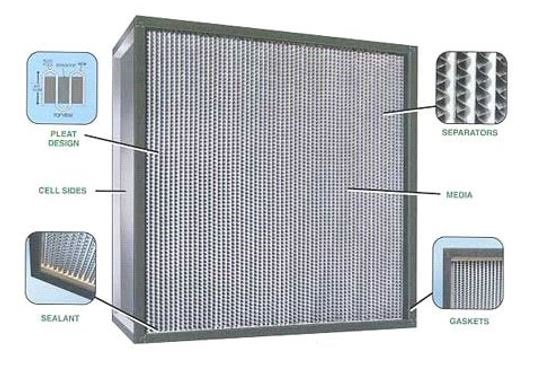

3️⃣ HEPA-Filtered Exhaust

According to ISO 14698-1, a HEPA-filtered exhaust is essential but often overlooked by many manufacturers.

This filter prevents sampled air from re-entering the environment, ensuring that cleanroom sterility is never compromised during monitoring operations.

4️⃣ Removable Petri Dish Holder

The Petri dish holder is the core of viable sampling — where microorganisms are captured and cultured.

It should be removable and easy to clean, reducing the risk of cross-contamination between samples and improving long-term equipment reliability.

5️⃣ Gas Sampling Capability

If your process involves compressed gases or plans to integrate them in the future, consider an active air sampler that supports gas sampling attachments.

This versatility ensures that your equipment remains compatible with process expansion and future cleanroom upgrades.

6️⃣ Autoclavable Components

Not all instruments or components can withstand autoclave sterilization.

Choose a model with removable, autoclavable parts to simplify the cleaning process and guarantee maximum sterility.

This feature not only saves time but also helps ensure consistent compliance with GMP and ISO hygiene standards.

7️⃣ Flexible Data Transfer Options

Modern cleanrooms demand seamless data management.

An ideal active air sampler should allow data storage, export, and integration with your LIMS or remote monitoring system.

Flexible connectivity improves process efficiency, traceability, and real-time reporting across your cleanroom network.

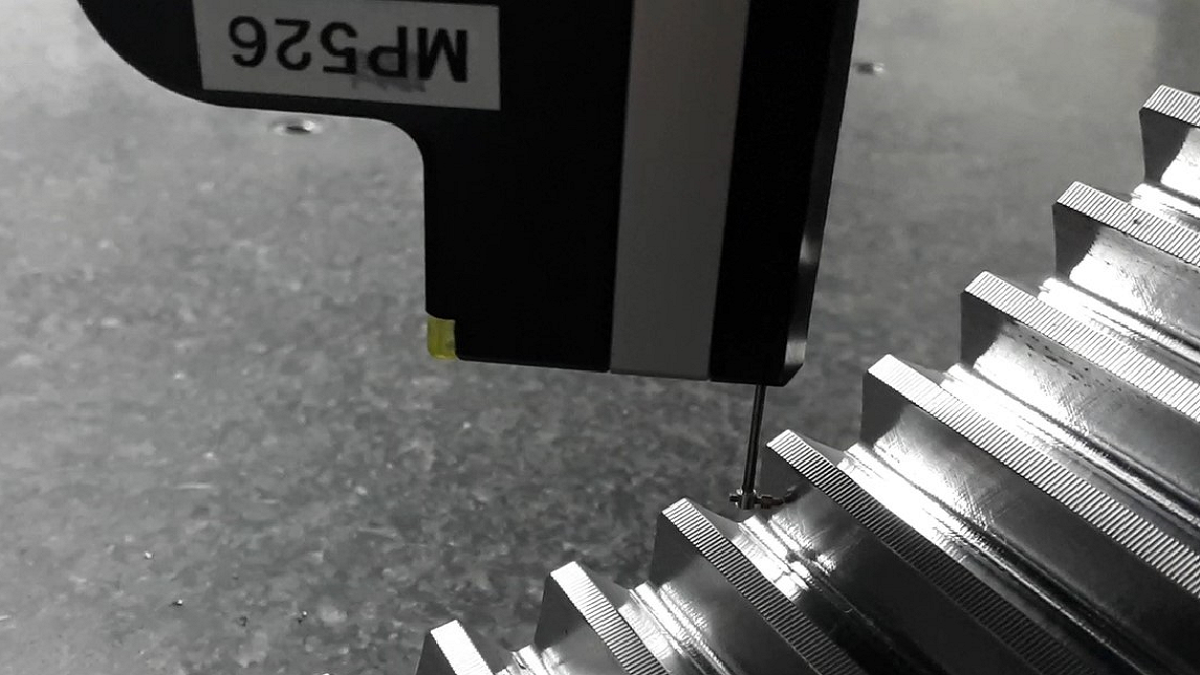

8️⃣ Optimized d50 Performance

The d50 value defines the sampler’s particle capture efficiency — at this point, 50% of particles of a given size impact the Petri dish and 50% exit through the pump.

If the d50 is too large (e.g., 10 µm), the device might miss smaller, more critical viable particles, leading to inaccurate results.

Ensure your air sampler is properly validated and ISO-certified for accurate and reliable contamination monitoring.

💡 Find the Right Air Sampler for Your Cleanroom

An active air sampler should be powerful, precise, and easy to integrate, ensuring continuous monitoring in sterile environments.

At Gera Hi-tech Vietnam, we provide Active Air Samplers optimized for pharmaceutical, electronics, and medical cleanrooms, meeting global standards such as ISO 14698, GMP, and EU Annex 1.

✅ Gera Hi-tech Vietnam – Comprehensive Cleanroom Monitoring Solutions

-

Lighthouse Airborne Particle Counters & Active Air Samplers

-

Real-time Environmental Monitoring Systems

-

GMP / ISO Compliance Solutions

-

Cleanroom Design, Consultation & Calibration Services

📞 Hotline: 0961 152 844

🌐 Website: gerahitech.vn